Where Excellence is Manufactured, and Trust is Guaranteed

Drive Defects to Zero through the relentless pursuit of Single-Digit PPM (Parts Per Million).

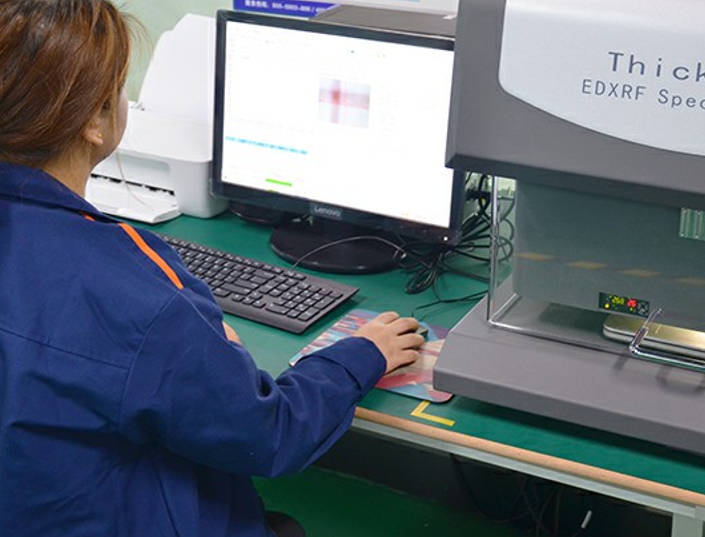

1. Inspection Contents: Connectors, wires, cables, terminals, accessories… 2. Inspection Items: Appearance, shape, materials, dimension, size, color… 3. Inspection Standards: Specifications, drawing, samples…

1. Inspection Contents: Cutting, stripping, crimping, injection, assemblying… 2. Inspection Methods: First article inspection, patrol , self , mutual inspection, and dynamic inspection throughout the entire process

1. Inspection Contents: Packing, Labels, marks, appearance, dimensions, electric performance test… 2. Inspection Instruments: Micrometer, caliper, electronic scale, hardness tester, Microscope, cable testing machine…